API 5L X65 PSL2 Seamless Pipe Suppliers

ISO 3183 Grade L450 Pipe Material, API 5L X65 Pipe Price in India

API 5L X65 Tubes, API 5L X65 Carbon Steel Pipe, API 5L X65 PSL2 Pipe Exporter in India

API 5L X65 Pipe Suppliers

L450 X65 PSL 1/ PSL 2 Pipe

- » API 5L X65 PSL2 specification

- » API 5L X65 Material Equivalent

- » API 5L Gr X65 Pipe Wall Thickness

- » API 5L X65 Pipe Dimensions

- » API 5L X65 PSL1 Pipe Schedule Chart

- » API 5L X65 Pipe Weight

- » API 5L X65 Chemical Composition

- » API 5L X65 Pipe Yield Strength

- » API 5L X65 Pipe Density

- » API 5L X65 PSL2 Pipe Price List

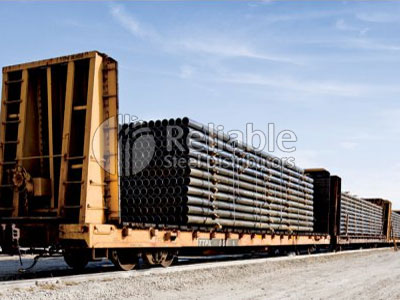

API 5L X65 Pipe Manufacturer in India

Reliable Steel Distributor is an award winner for best exports of API 5l x65 psl2 in India. We export API 5l x65 pipe schedule in countries like Malaysia, Indonesia, Singapore, Thailand, Oman, Abu Dhabi, Kuwait, UK & Nigeria. We are India’s 6th largest Manufacturer, Supplier & Exporters of excellent quality API 5l x65 pipe. At Reliable Steel, we provide a complete range of API 5l x65 material Products at factory prices. We provide API 5l grade x65q Pipe in all shapes and sizes and with any specifications as per clients need. We supply all of the high yield API 5l grade x65 pipe or API 5l x65 DSAW pipe supplies you need for use in the oil or gas industries.

Reliable Steel is in this domain for more than 20 years, and that makes us Prime Exporter of tuberia API 5l x65 psl2 & API 5l x65 tubes in India, Philippines, Kenya, Russia, Canada, Iran, Iraq & Tanzania. If you are Looking for API 5l x65 material or API 5l x65 erw pipes? We offer API 5l X65 SMLS pipes In India. Contact us for information regarding api 5l grade x65 psl2 specification, API 5l x65 chemical composition, API 5l x65 yield strength, API 5l x65 density and much more. Click here to get information regarding api 5l x65 uns number & api 5l x65 pipe weight.

Stockist of Norma API 5L X65, Caracteristicas Tuberia API 5L X65, API 5L X65 SMLS, API 5L X65 SAW Pipe Price of NSSMC, Jindal, ArcelorMittal MSL and ISMT

API 5L X65 Pipe Specifications

| Specification | API 5L X65, ASTM A1024 / A1024M, ISO 3183, API 5L X65m, API 5L X65mo psl2, API 5L X65M PSL2 |

| Scope | Covers Seamless, Welded, ERW pipes are suitable to convey water, gas and oil in both the oil and natural gas industries. |

| Manufacturing techniques |

API 5L X65 Welded

API 5L X65 Seamless Pipes API 5L X65 ERW API 5L X65 SAW |

| Hot-Dipped Galvanizing | May be ordered galvanized. |

API 5L Grade X65 Pipe Material

| Standard | API 5L X65 (Specification for Line Pipe – ANSI/API specification 5L – 44th Edition, October 1, 2007) |

|---|---|

| Sizes | Nominal Pipe Size 1/2" to 48 " O.D. Wall Thickness – Schedule 10 through 160, STD, XS, XXS. |

| Product Specification Level (PSL) | API 5L X65 PSL 2 API 5L X65 PSL 1 |

| Origin | Indian Origin, Japanese Origin, Korean Origin, European Origin, US Origin, Ukraine Origin, Russian Origin |

| Thickness | SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules |

| Applications | Oil Refineries, Petrochemicals, Power Generation (Nuclear/Thermal), Steel, Sugar, Boiler Equipments, Pressure Vessels and General Engineering Purposes |

| Pipe End | Plain, Bevel, Screwed, Threaded |

| API 5L X65 Pipes Type | Seamless / ERW / Welded / Fabricated / CDW |

| API 5L X65 Line Pipe Length | Single Random, Double Random & Required Length, Custom Size – 12 Meter lengths |

| Testing and Inspection Reports | EN 10204 3.1, Mill TC EN 10204 3.1, PMI Test Reports, Visual Inspection Reports, Destructive Test Report, Non Destructive Test Reports, NABL Approved Lab, Chemical and Mechanical Reports, India Boiler Regulations (IBR) Test Certificate, Third Party Inspection Reports |

| Packing | API 5L X65 GR. B Pipe Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| Finishes | Bare, Oiled, Mill Varnish, Galv, FBE, FBE Dual, 3LPE, 3LPP, Coal Tar, Concrete Coating and Tape Wrap.End Finishes:Beveled, Square Cut, Threaded & Coupled. |

| Application & uses | Suitable for Conveying gas, water, oil, and other liquefied media. |

| Other manufacturers of API 5L x65 nace | MSL, JSL, ISMT, USL, BAO, Lontrin, SMTM, TNRS, V&M and Wuxi |

| BS EN 10208-2:2009 | API 5L X65 pipelines for combustible fluids. Suitable to use in maximum operating pressure over 16 bar. |

| Value added service |

|

| Specialized in |

|

API 5L X65 ASME Equivalent / API 5L Grade X65 Material Equivalent Grades:

API 5L ASTM Equivalent

ASTM A1024 / A1024M