Alloy B2 Hastelloy Tube Suppliers in India

Hastelloy B2 Tube Stockist, Material grade B2 Tube dealers, Alloy B2 Tube manufacturer in India, Hastelloy B2 Seamless Tube distributor, Hastelloy Alloy B2 Seamless Tubing suppliers.

Hastelloy B2 Tube supplier

Hastelloy B2 Seamless Tube Stockist

Hastelloy B2 Tubing For Sale

We are No1 Hastelloy B2 Seamless Tube Manufacturer and Hastelloy B2 Tube suppliers. Hastelloy is a family of austenitic nickel-chromium-based superalloys. Hastelloy B2 Tube is a nonmagnetic, nickel-based high temperature alloy possessing an excellent combination of high strength, hot and cold workability, SCH40 Hastelloy B2 Tube is a nickel-chromium alloy with good carburization and oxidation resistance through 2000°. Hastelloy Alloy B2 Exhaust Tube is used in a variety of corrosion resisting applications. Hastelloy B2 Welded Tube is a nickel-chromium alloy designed for use at cryogenic temperatures and up to 2000˚F (1093˚C), Alloy B2 Tube is a nickel-chromium-iron alloy with good oxidation resistance at high temperatures and resistance to chloride-ion stress corrosion.

Reliable Steel Distributors is Manufacturer of Hastelloy B2 Tube in india also Exports Tube, Tube and Coils since 1997, in 2001 We were incorporated as a Supplier of Hastelloy B2 Welded Tube & we became stocking Distributor of Alloy B2 Tube in India. we are ISO 9001 & 14000 certified trader of Hastelloy B2 Tube in india, we maintain over 1200 ton Hastelloy Alloy B2 Exhaust Tube in huge variety sizes, shape which makes us one of the Biggest stockist of SCH40 Hastelloy B2 Tube in India.

Our widest stock of Hastelloy B2 Tube enable us for prompt delivery to Middle east, Gulf countries, far east asian countries in any emergency, later in year 1990, we were recognised as a leading Distributor of Hastelloy B2 Welded Tube in India, We are the only Supplier in india who maintains SCH40 Hastelloy B2 Tube in all Sizes. we started stocking Hastelloy Alloy B2 Exhaust Tube of other manufacturers of Hastelloy B2 Tube in Japan & Europe like Kobelco, Sandvik, Sanyo Special Steels & Wuxi. in year 1995, We became largest Stockist of Alloy B2 Tube in India, currently we have readyconel B2 Tube Schedule Chart stock of Hastelloy B2 Tube at our stockyard in Mumbai, Maharashtra.

- Hastelloy B2 Tube Specification

- Hastelloy B2 Tube Sizes

- Hastelloy B2 Tube Stock

- Hastelloy B2 Tube Weight Chart

- Hastelloy B2 Tube Pressure Rating

- Hastelloy B2 Tube Mechanical Properties

- Hastelloy B2 Tube Yield Strength

- Hastelloy B2 Tube Welding Tips

- Hastelloy B2 Tube Price

- Hastelloy B2 Tube Project Reference

Supplier & stockist of Alloy B2 Tubing, Hastelloy B2 Welded Tube stockholder, Alloy B2 Gas Tube in India, Hastelloy B2 Exhaust Tube Suppliers in Mumbai, India.

Specification of Hastelloy B2 Tube

Specifications for Hastelloy B2 boiler tubes are; BS 3074NA16, ASTM B 163, ASTM B 423, ASTM B 704, ASTM B 705, ASTM B 751, ASTM B 775, ASTM B 829, ASME SB 163, ASME SB 423, ASME SB 704, ASME SB 705, ASME SB 751, ASME SB 775, ASME SB 829, ASME Code Case 1936, DIN 17751, VdTÜV 432, ISO 6207

Size : 15 NB to 150 NB IN

Standards : SEAMLESS: ASTM B 163 / 423 / 829, WELDED: ASTM B 704 / 705 / 751 / 775

Type : Seamless / ERW / Welded / Fabricated / Hollow / LSAW Pipes

wall thickness: .035″ –.095′, (special wall thicknesses available)

Schedule : SCH5, SCH10, SCH40, STD, SCH80, SCH160

Finish : Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF

Form : Round, Square, Rectangular, Hydraulic, Straight or ‘U’ bent Tubes Etc.

Length : Single Random, Double Random & Cut Length.

End : Plain End, Beveled End, Treaded.

Marking: All Hastelloy Alloy B2 tubes are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.)

We can also cut, thread, and groove Hastelloy B2 Tubes to meet your specifications.

Stock List

|

Size

|

15 NB to 150 NB IN |

|---|---|

|

UNS N10276/W.Nr. 2.4819 Standard

|

ASTM B 622/B 829 & ASME SB 622/SB 829 (Seamless Tube), ASTM B 626/B 751 & ASME SB 626/SB 751 (Welded Tube), ASTM B 619/B 775 & ASME SB 619/SB 775 (Welded Pipe), ISO 6207 (Seamless Tube), DIN 17751, VdTÜV 400/12.98 |

|

Type

|

Seamless / ERW / Welded / Fabricated / Hollow / LSAW Pipes |

|

wall thickness

|

035″ –.095′, (special wall thicknesses available) |

|

Schedule

|

SCH5, SCH10, SCH40, STD, SCH80, SCH160 |

|

Finish

|

Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF |

|

Form

|

Round, Square, Rectangular, Hydraulic, Straight or ‘U’ bent Tubes Etc |

|

Length

|

Single Random, Double Random & Cut Length. |

|

End

|

Plain End, Beveled End, Treaded. |

|

Surface Finish

|

|

|

Marking

|

All Hastelloy Alloy C276 tubes are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

| We can also cut, thread, and groove Hastelloy C276 Tubes to meet your specifications. | |

B2 Hastelloy Alloy Seamless Tubes Manufacturer in India, exporter of Alloy B2 Welded Tube in India, Hastelloy Alloy B2 Round Tubes, Hastelloy Alloy B2 Seamless Tubes, Hastelloy B2 Furnace Tube Manufacturer in India, B2 Alloy Polish Tubing, Hastelloy B2 oil tube, Hastelloy B2 Mortar Tube Supplier, Exporter of Hastelloy B2 High Pressure Tube, Hastelloy B2 Heat Exchanger Tubes, Hastelloy B2 Radiant Tube wholesaler in India, Hastelloy B2 gas tube ar 15.

| Finish Code | Product Contact Surface (Max Ra)* |

Non-Product Contact Surface (Max Ra) |

|---|---|---|

| -PL | 20 µ-inch (0.5 µm) | 32 µ-inch (0.8 µm) |

| -SF | Sanitary Finish* | Mill Finish |

| -PU | Mill Finish | Mill Finish |

| *The sanitary finish offering is a finish better than traditional commercial grade tube finish. Suitable for applications in sanitary / high purity hygienic industries. | ||

| Hastelloy C276 Tubing Types | Grade C276 Tube Out diameter | Hastelloy C276 grade Tube Wall thickness | Hastelloy C276 grade tubing Length |

|---|---|---|---|

| NB Sizes (in stock) | 1/8” ~ 8” | SCH 5 / SCH 10 / SCH 40 / SCH 80 / SCH 160 | Upto 6 Meters |

| Seamless (Custom Sizes) | 5.0mm ~ 203.2mm | As per requirement | Upto 6 Meters |

| Welded (in Stock + Custom Sizes) | 5.0mm ~ 1219.2mm | 1.0 ~ 15.0 mm | Upto 6 Meters |

| Sanitary C276 tubing | 5.0mm ~ 203.2mm | As per requirement | Upto 6 Meters |

| All C276 tubing from Hitesh Steel complies with EN10204, 3.1. The material test report (MTR) will be provided with the Hastelloy C276 tubing. | |||

Also Check..

Types of Hastelloy B2 Seamless & Welded Tube

Hastelloy B2 Tube material

Hastelloy B2 Weld tube

Hastelloy B2 Lined tube

Hastelloy B2 Seamless tube

Hastelloy B2 Welded tube

Hastelloy B2 Exhaust tube

Hastelloy B2 square tube

Hastelloy B2 clad tube

Hastelloy B2 flex tube

| BEST PRICE OF | ||

|---|---|---|

|

|

|

Stock List

Alloy B2 Tubes Stock List

| Alloy | Product form | Dimension |

|---|---|---|

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; bright annealed, welded | 13.72 x 2.24 mm (¼”nb sch40s) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; annealed, welded | 17.15 x 1.65 mm (3/8″nb sch10s) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; bright annealed, welded | 17.15 x 2.31 mm (3/8″nb sch40s) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; annealed, welded | 21.34 x 2.11 mm (½”nb sch10s) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; bright solution annealed, welded | 21.34 x 2.77 mm (½”nb sch40s) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; solution annealed, welded | 26.67 x 2.11 mm (¾”nb SCH 10s) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; bright solution annealed, welded | 26.67 x 2.87 mm (¾”nb sch40s) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; pickled, welded | 33.40 x 2.77 mm (1″nb sch10s) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; annealed, welded | 33.40 x 3.38 mm, (1″nb sch40s) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; welded, annealed | 42.16 x 3.56 mm (1¼”nb sch40s) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; solution annealed, welded | 48.26 x 2.77 mm (1½” sch10s) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; bright solution annealed, welded | 48.26 x 3.68 mm, (1½” sch40s) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; pickled, welded | 60.33 x 2.77 mm, (2″nb sch10s) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; pickled, welded | 60.33 x 2.77 mm, (2″nb sch10s) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; seamless, cold drawn, pickled, solution annealed | 60.33 x 5.54 mm (2″nb sch80s) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; welded, annealed, pickled | 73.02 x 3.05 mm (2½”nb sch10s) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; bright solution annealed, welded | 88.9 x 3.05 mm, (3″nb sch10s) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; bright solution annealed, welded | 88.9 x 5.49 mm (3″nb sch40s) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; cold worked, solution annealed, welded | 114.3 x 3.05 mm (4″nb sch10s) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; cold drawn, annealed, welded | 3.17 x 0.51 mm (0.125″ x 0.02″) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; welded, bright annealed | 3.17 x 0.89 mm (0.125″ x 0.035″) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; welded, cold drawn, annealed | 4.0 x 0.25 mm |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; welded, annealed | 4.0 x 0.5 mm |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; welded, annealed | 5.0 x 0.25 mm |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; welded, cold drawn, annealed | 6.0 x 0.35 mm |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; welded, cold drawn, annealed | 6.0 x 0.5 mm |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; bright annealed, welded | 6.35 x 0.89 mm (¼” x 0.035″) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; welded, annealed | 8.0 x 0.5 mm |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; cold drawn, bright annealed, welded | 9.53 x 0.89 mm (3/8″ x 0.035″) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; welded, annealed | 10.0 x 0.5 mm |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; welded, cold drawn, annealed | 10.0 x 1.0 mm |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; annealed, welded | 12.0 x 0.5 mm |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; welded, cold drawn, annealed | 12.0 x 1.0 mm |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; cold drawn, bright annealed, welded | 12.7 x 0.89 mm (½” x 0.035″) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; cold drawn, bright annealed, welded | 12.7 x 1.65 mm (0.5″ x 0.065″) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; redrawn, welded | 14.2 x 2.5 mm |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; welded, bright solution annealed | 19.05 x 1.65 mm (¾” x 0.065″) |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; welded, bright annealed, drawn | 28.0 x 1.5 mm |

| ALLOY C-276 (15Cr/16Mo/4W) | Tubes; welded, cold drawn, annealed | 38.0 x 2.77 mm |

| Size | Wall Thickness | Hastelloy C276 tubing Style | Finish ID (Ra) |

Finish OD (Ra) |

|---|---|---|---|---|

| ½” (12.7 mm) | 0.065″ (1.651 mm) | Seamless Tubing | 20 µ-inch (0.5 µm) | 32 µ-inch (0.8 µm) |

| ¾” (19.05 mm) | 0.065″ (1.651 mm) | Seamless Tubing | 20 µ-inch (0.5 µm) | 32 µ-inch (0.8 µm) |

| 1” (25.4 mm) | 0.065″ (1.651 mm) | Seamless Tubing | 20 µ-inch (0.5 µm) | 32 µ-inch (0.8 µm) |

| 1½” (38.1 mm) | 0.065″ (1.651 mm) | Welded Tubing | Sanitary Finish* | Mill Finish |

| 2” (50.8 mm) | 0.065″ (1.651 mm) | Welded Tubing | Sanitary Finish* | Mill Finish |

| 3″ (76.2 mm) | 0.065″ (1.651 mm) | Welded Tubing | Mill Finish | Mill Finish |

weight chart

Alloy B2 Tubes weight chart

Pipes Sizes

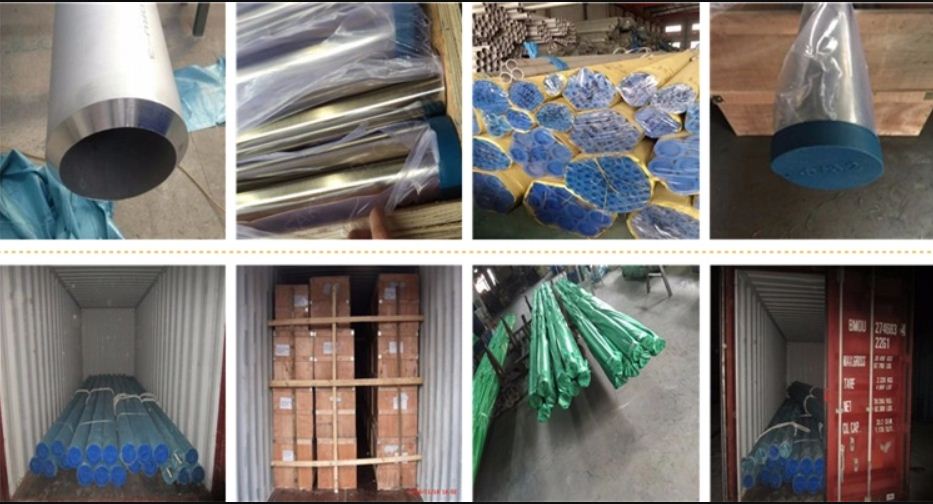

Hastelloy B2 Tube Packing & Shipping

Pressure Rating

Hastelloy B2 Tube Pressure Rating

| Grade |

Maximum internal pressure, ksi

|

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 100°F | 200°F | 300°F | 400°F | 500°F | B2°F | 700°F | Comments | |||

| N06B2 :1 | 8.02 | 8.02 | 8.02 | 8.02 | 8.02 | 8.02 | 8.02 | B167 OD>5″ and hotworked | ||

| N06B2 :2 | 9.6 | 9.6 | 9.6 | 9.6 | 9.6 | 9.6 | 9.6 | B167 OD<=5″ and hotworked + OD>5″ and coldworked | ||

| N06B2 :3 | 11.19 | 11.19 | 11.19 | 11.19 | 11.19 | 11.19 | 11.19 | B167 OD<=5″ and coldworked | ||

|

Selected wall tolerance: ±10%; OUTSIDE DIAMETER AND WALL THICKNESS (MM): 6 x 1

|

||||||||||

| Grade |

Maximum internal pressure, ksi

|

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 100°F | 200°F | 300°F | 400°F | 500°F | B2°F | 700°F | Comments | |||

| N06B2 :1 | 392 | 392 | 392 | 392 | 392 | 392 | 392 | B167 OD>5″ and hotworked | ||

| N06B2 :2 | 470 | 470 | 470 | 470 | 470 | 470 | 470 | B167 OD<=5″ and hotworked + OD>5″ and coldworked | ||

| N06B2 :3 | 547 | 547 | 547 | 547 | 547 | 547 | 547 | B167 OD<=5″ and coldworked | ||

|

Selected wall tolerance: ±10%; OUTSIDE DIAMETER AND WALL THICKNESS (MM): 8 x 1

|

||||||||||

| Grade |

Maximum internal pressure, ksi

|

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 100°F | 200°F | 300°F | 400°F | 500°F | B2°F | 700°F | Comments | |||

| N06B2 :1 | 284 | 284 | 284 | 284 | 284 | 284 | 284 | B167 OD>5″ and hotworked | ||

| N06B2 :2 | 340 | 340 | 340 | 340 | 340 | 340 | 340 | B167 OD<=5″ and hotworked + OD>5″ and coldworked | ||

| N06B2 :3 | 397 | 397 | 397 | 397 | 397 | 397 | 397 | B167 OD<=5″ and coldworked | ||

Disclaimer: The pressures Shown in the above table are given for reference only. The Dimensioning of piping systems can vary depending on other factors like thermal stresses, external forces, dead weight etc. Design should be made according to regulations from local authorities

The Most Important standards of Tubes in pressure vessels and boilers are:

- American standard ASME Boiler and Pressure Vessel Code Section VIII Division 1 and 2.

- Pressure Equipment Directive 97/23/PG (PED)

- (European applications) Machine Directive 2006/42/EG

Hastelloy B2 Tube Welding Tips

Hastelloy is a family of austenitic nickel-chromium-based superalloys. Hastelloy B2 Tube is a nonmagnetic, nickel-based high temperature alloy possessing an excellent combination of high strength, hot and cold workability, SCH40 Hastelloy B2 Tube is a nickel-chromium alloy with good carburization and oxidation resistance through 2000°. Hastelloy Alloy B2 Exhaust Tube is used in a variety of corrosion resisting applications. Hastelloy B2 Welded Tube is a nickel-chromium alloy designed for use at cryogenic temperatures and up to 2000˚F (1093˚C), Alloy B2 Tube is a nickel-chromium-iron alloy with good oxidation resistance at high temperatures and resistance to chloride-ion stress corrosion.

Chemical Composition

Hastelloy B2 Tube Yield Strength

Chemical Composition Hastelloy Alloy B2 Tube

| Hastelloy C276 | Ni | C | Mo | Mn | Si | Fe | P | S | Co | Cr |

| Balance | 0.010 max | 15.00 – 17.00 | 1.00 max | 0.08 max | 4.00 – 7.00 | 0.04 max | 0.03 max | 2.5 max | 14.50 – 16.50 |

Mechanical Properties

Hastelloy B2 Tube Mechanical Properties

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 8.89 g/cm3 | 1370 °C (2500 °F) | Psi – 52,000 , MPa – 355 | Psi – 1,15,000 , MPa – 790 | 40 % |

Equivalent Grades

Hastelloy B2 Seamless and Welded Tubes Equivalent Grades

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST |

| Hastelloy C276 | N10276 | 2.4819 | – | NiMo16Cr15W | NW 0276 | – | ХН65МВУ |

Weldability of materials

Hastelloy Alloy B2 Tube Weldability of materials

| Table 1: Filler selection for nickel alloys | ||||

|---|---|---|---|---|

| Parent Alloy | Filler designations | Comments | ||

| Alloy | BS EN ISO 18274 | AWS A5.14 | Trade names | |

| Pure nickel | ||||

| Nickel 200 | Ni 2061 | ERNi-1 | Nickel 61 | Matching filler metal normally contains 3%Ti |

| Nickel Copper | ||||

| Alloy 400 | Ni 4060 | ERNiCu-7 | Monel 60 | Matching filler metal contains additions of Mn, Ti and Al |

| Nickel Chromium | ||||

| Brightray S | Ni 6076 | – | NC 80/20 | Ni-Cr and Ni-Cr-Fe filler metals may be used |

| Nimonic 75 | Ni 6076 | – | NC 80/20 | |

| Nickel-Chromium-Iron | ||||

| Alloy B2 | Ni 6625 | ERNiCrMo-3 | Hastelloy 625 Thermanit 21/33 |

Usually welded with Ni-Cr-X alloys, but more nearly matching consumables are available which contain higher C and also Nb |

| Alloy B2 | Ni 6082 | ERNiCr-3 | Hastelloy 82 | Matching filler metal contains Nb addition |

| Alloy B2 | Ni 7B2 | ERNiFeCr-2 | Hastelloy B2 | Matching filler metal is normally used but Alloy 625 is an alternative consumable , if postweld heat treatment is not applied |

| Nickel-Chromium-Molybdenum | ||||

| Alloy 625 | Ni 6625 | ERNiCrMo-3 | Hastelloy 625 | Filler metal is also used widely for cladding and dissimilar welds |

| Hastelloy C-22 | Ni 6022 | ERNiCrMo-10 | Hastelloy C-22 | |

| Nickel-Molybdenum | ||||

| Hastelloy B-2 | Ni 1066 | ERNiMo-7 | Hastelloy B-2 | Corrosion resistant alloys require matching fillers |

Hastelloy B2 Tube Price

| PRODUCT NAME | PACK QTY | PRICE |

|---|---|---|

| 3.17mm OD x 0.51mm Thick x 1000mm Length | 1 |

£96.00

|

| 3.17mm OD x 0.51mm Thick x 1000mm Length | 3 |

£216.00

|

| 3.17mm OD x 0.51mm Thick x 1000mm Length | 5 |

£324.00

|

| 3.17mm OD x 0.51mm Thick x 1000mm Length | 10 |

£588.00

|

| 3.17mm OD x 0.51mm Thick x 1000mm Length | 15 |

£818.00

|

| 3.17mm OD x 0.51mm Thick x 2000mm Length | 1 |

£128.00

|

| 3.17mm OD x 0.51mm Thick x 2000mm Length | 3 |

£306.00

|

| 3.17mm OD x 0.51mm Thick x 2000mm Length | 5 |

£456.00

|

| 3.17mm OD x 0.51mm Thick x 2000mm Length | 10 |

£817.00

|

| 3.17mm OD x 0.51mm Thick x 2000mm Length | 15 |

£1, 112.00

|

Client Reference and Applications

Client Reference and Applications

Ontario Power Generation Inc

700 University Ave, Toronto, ON M5G 1Z5, Canada

Hydro One

483 Bay St, Toronto, ON M5G 1P5, Canada

ABB Australia

Karratha Industrial Estate WA 6714, Australia

Energy Brix Australia Corp.

412 Commercial Rd, Morwell VIC 3840, Australia

AKSA Power Generation USA

371 Exchange St, West Monroe, LA 71292, USA

Siemens Energy

8060 Flint St, Lenexa, KS 66214, USA

RWE Generation UK

Little Barford Power Station, Saint Neots PE19 6YT, UK

Energy UK

Charles House, 5-11 Regent St, St. James’s, London SW1Y 4LR, UK

Kapar Energy Ventures

Kampung Tok Muda, 45B2 Kapar, Selangor, Malaysia

Stesen Janaelektrik Sultan Salahuddin Abdul Aziz

Jalan Tok Muda, Selangor, Kampung Tok Muda, 42200 Kapar, Selangor, Malaysia

Dana Water Heaters & Coolers Factory llc

Dubai – United Arab Emirates

Tuas Power Generation

60 Tuas South Avenue 9, Singapore 637607

Cummins Power Generation (S) Pte Ltd

10 Toh Guan Rd, Singapore 608838

Barakah Nuclear Power Plant

Barakah – Abu Dhabi – United Arab Emirates

Power Electric Switchgear Factory

Abu Dhabi – United Arab Emirates

Shams Solar Power Station

Madinat Zayed- Al Gharbia- – Abu Dhabi – UAE

Hassyan Power Plant

Dubai – United Arab Emirates

AKSA Power Generation FZE

Jebel Ali Free Zone – Dubai – United Arab Emirates

Al Mirfa Power and Desalination Plant

Al Mirfa – Abu Dhabi – United Arab Emirates

U-Power Generation FZC

Sharjah International Airport – Sharjah – United Arab Emirates

Fujairah F2 Plant

Fujairah – United Arab Emirates

Fayfa Chemicals Factory LLC

22A, AL QUOZ INDUSTRIAL AREA 3 – Dubai – United Arab Emirates

Hastelloy B2 Tube Sizes

Hastelloy B2 Tube Sizes

| Wall | Sizes ( O.D.) |

|---|---|

| .010 | 1/16″ , 1/8″ , 3/16″ |

| .020 | 1/16″ , 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ |

| .012 | 1/8″ |

| .016 | 1/8″ , 3/16″ |

| .028 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 3/4″ , 1″ , 1 1/2″ , 2″ |

| .035 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 7/16″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .049 | 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/8″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .065 | 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 3/4″ , 2″ , 2 1/2″ , 3″ |

| .083 | 1/4″ , 3/8″ , 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 7/8″ , 2″ , 2 1/2″ ,3″ |

| .095 | 1/2″ , 5/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .109 | 1/2″ , 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .120 | 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 2 1/4″ , 2 1/2″ , 3″ |

| .125 | 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 3″ , 3 1/4″ |

| .134 | 1″ |

| .250 | 3″ |

| .375 | 3 1/2″ |