ASTM A672 Welded Pipe supplier

ASTM A 672 Polished Pipes Exporter, ASTM A 672 CS EFW Tubing Leading Manufacturers, CS Welded Round Tubes stockist, ASTM A 672 carbon Steel ERW Pipes Exporter.

ASTM A 672 Carbon Steel Welded Pipes & Tubes, ASTM A 672 CS Rectangular Welded Pipes, ASTM A 672 CS Welded Rectangular Pipes & Tubes Suppliers, Carbon Steel Welded Square Pipes & Tubes Manufacturer.

ASTM A672 Welded Pipe For Sake

ASTM A672 Welded Pipe Best Price

ASTM A672 Welded Pipe

ASTM A672 Welded Pipe specification handles electric-fusion-welded steel pipe with added filler metal added, ASTM A672 Welded Pipe fabricated from pressure vessel quality plate of several analyses and strength levels. ASTM A672 Welded Pipe is suitable for high-pressure service at atmospheric and lower temperatures. ASTM A672 Welded Pipe may or may not be required Heat treatment to attain the desired properties. when additional testing or examination is desired. Supplementary requirements are provided for use.

Reliable Steel Distributors is Manufacturer of ASTM A672 Welded Pipe in india also Exports Pipe, Pipe and Coils since 1997, in 2001 We were incorporated as a Supplier of ASTM A672 Welded Pipe & we became stocking Distributor of ASTM A672 Welded Pipe in India. we are ISO 9001 & 14000 certified trader of ASTM A672 Welded Pipe in india, we maintain over 1200 ton ASTM A672 Welded Exhaust Pipe in huge variety sizes, shape which makes us one of the Biggest stockist of SCH40 ASTM A672 Welded pipe in India.

Our widest stock of ASTM A672 Welded Pipe enable us for prompt delivery to Middle east, Gulf countries, far east asian countries in any emergency, later in year 1990, we were recognised as a leading Distributor of ASTM A672 Welded Pipe in India, We are the only Supplier in india who maintains SCH40 ASTM A672 Welded pipe in all Sizes. we started stocking ASTM A672 Welded Exhaust Pipe of other manufacturers of ASTM A672 Welded Pipe in Japan & Europe like Kobelco, Sandvik, Sanyo Special Steels & Wuxi. in year 1995, We became largest Stockist of Alloy 600 Pipe in India, currently we have ready stock of ASTM A672 Welded Pipe at our stockyard in Mumbai, Maharashtra.

- What is ASTM A672 Welded Carbon Steel EFW Pipe?

- specification of ASTM A672 Welded

- ASTM A672 Welded Characteristics

- manufacturing process of ASTM A672 Welded

- ASTM A672 Welded Class

- Grades A672 Pipe

- Types of ASTM A672 Welded Carbon Steel EFW Pipe

- Heat Treatment Parameters of ASTM A672 Welded

- Chemical Composition of ASTM A672 Welded

- Mechanical Properties of ASTM A672 Welded

- ASTM A672 Welded Applications

Specification of ASTM A672 Welded Pipe

Specifications : A672

Pipes & Tubes : 1/2″ NB – 60″ NB

ERW Pipes & Tubes : 1/2″ NB – 24″ NB

SAW Pipes & Tubes : 16″ NB – 100″ NB

Thickness : SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules

Type : ERW / Welded / Fabricated / CDW

Form : Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes

Length : Single Random, Double Random & Required Length, Custom Size – 12 Meter lengths

End : Plain End, Beveled End, Treaded

| Standard | : | A672 |

| Sizes Range | : | 12″ – 24″ |

| Schedules | : | SS 5, S 10, S 20, S 40, S 60, S XS, S 80, S 100, S 120, S 140, S 160, S XXS |

| Pipe Grade | Type of Steel | ASTM Specification | |

|---|---|---|---|

| No. | Grade | ||

| ASTM A672 Gr CA 55 | Plain carbon | A 285/A 285M | C |

| ASTM A672 Gr CB 60 | plain carbon, killed | A 515/A 515M | 60 |

| ASTM A672 Gr CB 65 | plain carbon, killed | A 515/A 515M | 65 |

| ASTM A672 Gr CB 70 | plain carbon, killed | A 515/A 515M | 70 |

| ASTM A672 Gr CC60 | plain carbon, killed, fine grain | A 516/A 516M | 60 |

| ASTM A672 Gr CC 65 | plain carbon, killed, fine grain | A 516/A 516M | 65 |

| ASTM A672 Gr CC 70 | plain carbon, killed, fine grain | A 516/A 516M | 70 |

| ASTM A672 Gr CD 70 | manganese-silicon, normalized | A 537/A 537M | 1 |

| ASTM A672 Gr CD 80 | manganese-silicon, quenched and tempered | A 537/A 537M | 2 |

Types of ASTM A672 Welded Seamless & Welded Pipe

Seamless ASTM A672 Welded Pipe

ASTM A672 Welded Pipes

Cold Drawn ASTM A672 Welded Pipe

ASTM A672 Welded ERW Pipe

ASTM A672 Welded EFW Pipe

Perforated ASTM A672 Welded Pipe

Hot finished ASTM A672 Welded Pipe

ASTM A672 Welded Sanitary Pipe

Heavy Wall ASTM A672 Welded Pipe

SCH 120 ASTM A672 Welded Pipe

SCH 80 ASTM A672 Welded Pipe

SCH 60 ASTM A672 Welded Pipe

SCH 40 ASTM A672 Welded Pipe

SCH 30 ASTM A672 Welded Pipe

SCH 20 ASTM A672 Welded Pipe

SCH 5 ASTM A672 Welded Pipe

SCH 10 ASTM A672 Welded Pipe

Mill Finish ASTM A672 Welded Pipe

ASTM A672 Welded Pipe material

ASTM A672 Welded Weld Pipe

ASTM A672 Welded Lined Pipe

ASTM A672 Welded Seamless Pipe

ASTM A672 Welded Pipe

ASTM A672 Welded Exhaust Pipe

ASTM A672 Welded square Pipe

ASTM A672 Welded clad Pipe

ASTM A672 Welded flex Pipe

ASTM A672 Welded Capillary Pipe

Polished ASTM A672 Welded Pipe

Thin-Wall ASTM A672 Welded Pipe

ASTM A672 Welded Triangle Pipe

ASTM A672 Welded Slot Round Pipe

ASTM A672 Welded Electropolished Pipe

ASTM A672 Welded U Shaped Pipe

ASTM A672 Welded Handrail Pipe

ASTM A672 Welded Hexagonal Pipe

ASTM A672 Welded Precision Pipe

ASTM A672 Welded Square Pipe

High Pressure ASTM A672 Welded Pipe

ASTM A672 Welded Ornamental Pipe

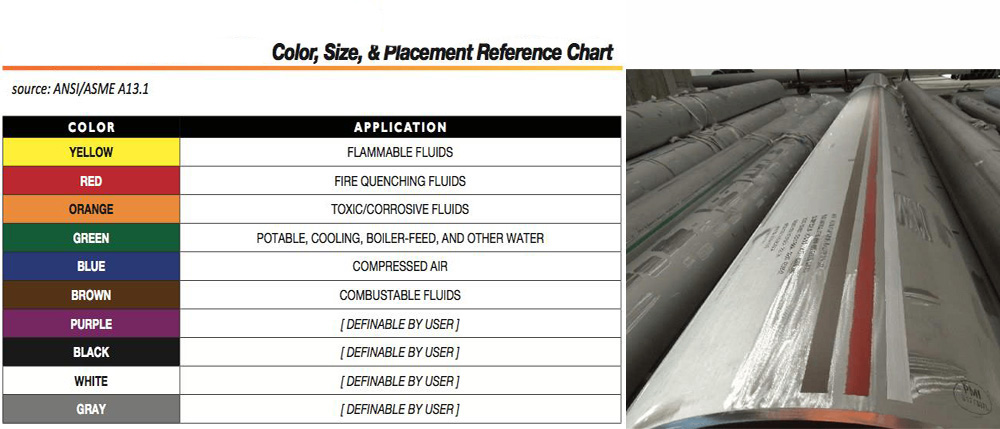

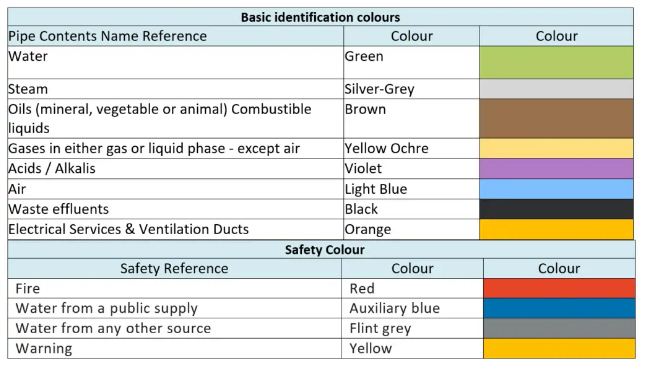

ASTM A672 Welded Colour Coated Pipe

ASTM A672 Welded Rectangular Pipe

| » ASTM A 672 Welded Tubing » ASTM A 672 Welded ERW Pipes Manufacturer » ASTM A 672 Welded Pipes » ASTM A 672 Welded Square Tubes » ASTM A 672 Welded Line Pipes Manufacturer » Carbon Steel Welded Round Pipes & Tubes » Carbon Steel Welded Rectangular Pipes Distributors » ASTM A 672Welded ERW Tubing » ASTM A 672 Welded Tubes » ASTM A 672 Welded Tubing Suppliers |

» ASTM A 672 Welded CS Pipes & Tubes Suppliers » ASTM A 672 Welded Pipes & Tubes Dealers » ASTM A 672 Welded Tubes » ASTM A 672 Welded Pipes » ASTM A 672 Welded ERW Pipes Stockiest in India » ASTM A 672 Welded Carbon Steel Welded Black Round Pipes » ASTM A 672 Carbon Steel Capillary Tube » ASTM A 672 Carbon Steel Welded Tubing » CS Hydraulic Tubes Suppliers » ASTM A 672 Welded Carbon Steel U Shaped Tubing Stockholder |

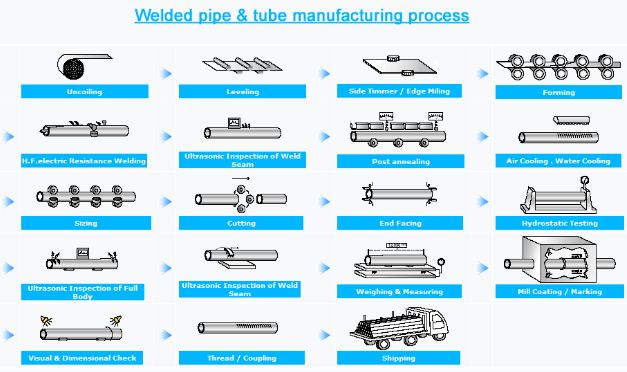

ASTM A672 Gr CA55 Carbon Steel EFW Pipe manufacturing process

ASTM A672 Welded Heat Treatment Parameters

| Pipe Grade | ASTM Specification and Grade | Post-Weld Heat-Treatment Temperature Range °F(°C) | Normalizing Temperature, max, °F(°C) | Quenching Temperature max, °F(°C) | Tempering Temperature min, °F(°C) |

|---|---|---|---|---|---|

| ASTM A672 CA 55 | A 285/A 285M (C) | 1100-1250 (590-680) | 1700 (925) | – | – |

| ASTM A672 CB 60 | A 515/A 515M (60) | 1100-1250 (590-680) | 1750 (950) | – | – |

| ASTM A672 CB 65 | A 515/A 515M (65) | 1100-1250 (590-680) | 1750 (950) | – | – |

| ASTM A672 CB 70 | A 515/A 515M (70) | 1100-1250 (590-680) | 1750 (950) | – | – |

| ASTM A672 CC60 | A 516/A 516M (60) | 1100-1250 (590-680) | 1750 (925) | 1650 (900) | 1200 (650) |

| ASTM A672 CC 65 | A 516/A 516M (65) | 1100-1250 (590-680) | 1750 (925) | 1650 (900) | 1200 (650) |

| ASTM A672 CC 70 | A 516/A 516M (70) | 1100-1250 (590-680) | 1750 (925) | 1650 (900) | 1200 (650) |

| ASTM A672 CD 70 | A 537/A 537M (1) | 1100-1250 (590-680) | 1750 (925) | – | – |

| ASTM A672 CD 80 | A 537/A 537M (2) | 1100-1250 (590-680) | – | 1650 (900) | 1100 (590) |

ASTM A672 Welded Mechanical Properties

| Products | Steel Grade | BASE METAL MECHANICAL COMPOSITION | Welding point tensile strength (N/mm2) | Remarks | |||

| Yield point (N/mm2) | Tensile Stregth (N/mm2) | Test Pieces | Elongation (%) | ||||

| Pipes for pressure service ASTM A671, A672 | -/A45 | -/165 | -/310~450 | – | -/30 | -/310~450 | A671/ A672 |

| -/A50 | -/185 | -/345~485 | -/28 | -/345~485 | |||

| CA55/A55 | 205 | 380~515 | 27 | 380~515 | |||

| -/B55 | -/205 | -/380~515 | -/27 | -/380~515 | |||

| CB60/B60 | 220 | 415~550 | 25 | 415~550 | |||

| CB65/B65 | 240 | 450~585 | 23 | 450~585 | |||

| CB70/B70 | 260 | 485~620 | 21 | 485~620 | |||

| -/C55 | -/205 | -/380~515 | -/27 | -/380~515 | |||

| CC60/C60 | 220 | 415~550 | 25 | 415~550 | |||

| CC65/C65 | 240 | 450~585 | 23 | 450~585 | |||

| CC70/C70 | 260 | 485~620 | 21 | 485~620 | |||

ASTM A672 Welded Chemical Composition

| Specification | Steel grade | Chemical composition | Remarks | |||||

| C | Si | Mn | P | S | Ti | |||

| Pipes for pressure service ASTM A671, A672 |

-/A45 | -/0.17 | – | 0.98 | 0.035 | 0.035 | – | A671/ A672 |

| -/A50 | -/0.22 | – | ||||||

| CA55/A55 | 0.28 | – | ||||||

| -/B55 | -/0.20 | 0.13 ~0.45 |

||||||

| CB60/B60 | 0.24 | |||||||

| CB65/B65 | 0.28 | |||||||

| CB70/C70 | 0.31 | 1.30 | ||||||

| -/C55 | -/0.18 | 0.55 ~0.98 |

||||||

| CC60/C60 | 0.21 | |||||||

| CC65/C65 | 0.24 | 0.79 ~1.30 |

||||||

| CC70/C70 | 0.27 | |||||||

ASTM A672 Welded Characteristics

- Excellent strength and ductility, Low-temperature services serve at -45F°F (-45°C)

- greater toughness and Better weldability

- Conductivity than alloy steels

- Higher strength with low coefficients of thermal

ASTM A672 Welded Class

| Class | Heat treatment on pipe | RT | Pressure test | |

|---|---|---|---|---|

|

A672 Class 11

|

none

|

?

|

?

|

?

|

|

A672 Class 12

|

none

|

?

|

?

|

?

|

|

A672 Class 13

|

none

|

?

|

?

|

?

|

|

A672 Class 20

|

stress relieved

|

PHWT

|

?

|

?

|

|

A672 Class 21

|

stress relieved

|

PHWT

|

?

|

?

|

|

A672 Class 22

|

stress relieved

|

PHWT

|

?

|

?

|

|

A672 Class 23

|

stress relieved

|

PHWT

|

?

|

?

|

|

A672 Class 30

|

normalized

|

?

|

?

|

|

|

A672 Class 31

|

normalized

|

?

|

?

|

|

|

A672 Class 32

|

normalized

|

?

|

?

|

|

|

A672 Class 33

|

normalized

|

?

|

?

|

|

|

Class

|

Heat Treatment on Pipe

|

Radiography

|

Pressure Test

|

|---|---|---|---|

|

A672 Class 10

|

none

|

none

|

none

|

|

A672 Class 11

|

none

|

9

|

none

|

|

A672 Class 12

|

none

|

9

|

8.3

|

|

A672 Class 13

|

none

|

none

|

8.3

|

|

A672 Class 21

|

stress relieved, see 6.3.1

|

none

|

none

|

|

A672 Class 21

|

stress relieved, see 6.3.1

|

9

|

none

|

|

A672 Class 22

|

stress relieved, see 6.3.1

|

9

|

8.3

|

|

A672 Class 23

|

stress relieved, see 6.3.1

|

none

|

8.3

|

|

A672 Class 31

|

normalized, see 6.3.2

|

none

|

none

|

|

A672 Class 31

|

normalized, see 6.3.2

|

9

|

none

|

|

A672 Class 32

|

normalized, see 6.3.2

|

9

|

8.3

|

|

A672 Class 33

|

normalized, see 6.3.2

|

none

|

8.3

|

|

A672 Class 40

|

normalized and tempered, see 6.3.3

|

none

|

none

|

|

A672 Class 43

|

normalized and tempered, see 6.3.3

|

9

|

none

|

|

A672 Class 43

|

normalized and tempered, see 6.3.3

|

9

|

8.3

|

|

A672 Class 43

|

normalized and tempered, see 6.3.3

|

none

|

8.3

|

|

A672 Class 50

|

quenched and tempered, see 6.3.4

|

none

|

none

|

|

A672 Class 51

|

quenched and tempered, see 6.3.4

|

9

|

none

|

|

A672 Class 52

|

quenched and tempered, see 6.3.4

|

9

|

8.3

|

|

A672 Class 53

|

quenched and tempered, see 6.3.4

|

none

|

8.3

|

|

A672 Class 60

|

normalized and precipitation heat none none treated

|

none

|

none

|

|

A672 Class 61

|

normalized and precipitation heat none none treated

|

9

|

none

|

|

A672 Class 62

|

normalized and precipitation heat none none treated

|

9

|

8.3

|

|

A672 Class 63

|

normalized and precipitation heat none none treated

|

none

|

8.3

|

|

A672 Class 70

|

normalized and precipitation heat none none treated

|

none

|

none

|

|

A672 Class 71

|

normalized and precipitation heat none none treated

|

9

|

none

|

|

A672 Class 72

|

normalized and precipitation heat none none treated

|

9

|

8.3

|

|

A672 Class 73

|

normalized and precipitation heat none none treated

|

none

|

8.3

|

ASTM A672 Welded Applications

- Storage for natural gas

- FEED for heaters

- LNG terminals

- Hydrocracking

- High pressure applications

- Industries served

- Process piping applications

- Flares stacks

- Power plant piping

- Heat exchangers

- Welded pressure vessels for the storage of cryogens

- Refineries

Pipe Specification to Manufacturer A672 Grade Welded Carbon Steel EFW LSAW Pipes

| Pipe Grade | Type of Steel | ASTM Specification | |

|---|---|---|---|

| No. | Grade / Class / Type | ||

|

A672 Grade CA 55

|

plain carbon

|

A285/A285M

|

Gr C

|

|

A672 Grade CB 60

|

plain carbon, killed

|

A515/A515M

|

Gr 60

|

|

A672 Grade CB 65

|

plain carbon, killed

|

A515/A515M

|

Gr 65

|

|

A672 Grade CB 70

|

plain carbon, killed

|

A515/A515M

|

Gr 70

|

|

A672 Grade CC60

|

plain carbon, killed, fine grain

|

A516/A516M

|

Gr 60

|

|

A672 Grade CC 65

|

plain carbon, killed, fine grain

|

A516/A516M

|

Gr 65

|

|

A672 Grade CC 70

|

plain carbon, killed, fine grain

|

A516/A516M

|

Gr 70

|

|

A672 Grade CD 70

|

manganese-silicon, normalized

|

A537/A537M

|

Cl 1

|

|

A672 Grade CD 80

|

manganese-silicon, quenched and tempered

|

A537/A537M

|

Cl 2

|

|

A672 Grade CF 65

|

nickel steel

|

A203/A203M

|

Gr A

|

|

A672 Grade CF 70

|

nickel steel

|

A203/A203M

|

Gr B

|

|

A672 Grade CF 65

|

nickel steel

|

A203/A203M

|

Gr D

|

|

A672 Grade CF 70

|

nickel steel

|

A203/A203M

|

Gr E

|

|

CG 100

|

9 % nickel

|

A353/A353M

|

|

|

CH 115

|

9 % nickel

|

A553/A553M

|

Type 1

|

|

CJA 115

|

alloy steel, quenched and tempered

|

A517/A517M

|

Gr A

|

|

CJB 115

|

alloy steel, quenched and tempered

|

A517/A517M

|

Gr B

|

|

CJE 115

|

alloy steel, quenched and tempered

|

A517/A517M

|

Gr E

|

|

CJF 115

|

alloy steel, quenched and tempered

|

A517/A517M

|

Gr F

|

|

CJH 115

|

alloy steel, quenched and tempered

|

A517/A517M

|

Gr H

|

|

CJP 115

|

alloy steel, quenched and tempered

|

A517/A517M

|

Gr P

|

|

CK 75

|

carbon-manganese-silicon

|

A299/A299M

|

Gr A

|

|

CP85

|

alloy steel, age hardening, quenched and precipitation heat treated

|

A736/A736M

|

Gr A, Class 3

|

Client Reference and Applications

Ontario Power Generation Inc

700 University Ave, Toronto, ON M5G 1Z5, Canada

Hydro One

483 Bay St, Toronto, ON M5G 1P5, Canada

ABB Australia

Karratha Industrial Estate WA 6724, Australia

Energy Brix Australia Corp.

412 Commercial Rd, Morwell VIC 3840, Australia

AKSA Power Generation USA

371 Exchange St, West Monroe, LA 71292, USA

Siemens Energy

8060 Flint St, Lenexa, KS 66214, USA

RWE Generation UK

Little Barford Power Station, Saint Neots PE19 6YT, UK

Energy UK

Charles House, 5-11 Regent St, St. James’s, London SW1Y 4LR, UK

Kapar Energy Ventures

Kampung Tok Muda, 45600 Kapar, Selangor, Malaysia

Stesen Janaelektrik Sultan Salahuddin Abdul Aziz

Jalan Tok Muda, Selangor, Kampung Tok Muda, 42200 Kapar, Selangor, Malaysia

Dana Water Heaters & Coolers Factory llc

Dubai – United Arab Emirates

Tuas Power Generation

60 Tuas South Avenue 9, Singapore 637607

Cummins Power Generation (S) Pte Ltd

10 Toh Guan Rd, Singapore 608838

Barakah Nuclear Power Plant

Barakah – Abu Dhabi – United Arab Emirates

Power Electric Switchgear Factory

Abu Dhabi – United Arab Emirates

Shams Solar Power Station

Madinat Zayed- Al Gharbia- – Abu Dhabi – UAE

Hassyan Power Plant

Dubai – United Arab Emirates

AKSA Power Generation FZE

Jebel Ali Free Zone – Dubai – United Arab Emirates

Al Mirfa Power and Desalination Plant

Al Mirfa – Abu Dhabi – United Arab Emirates

U-Power Generation FZC

Sharjah International Airport – Sharjah – United Arab Emirates

Fujairah F2 Plant

Fujairah – United Arab Emirates

Fayfa Chemicals Factory LLC

22A, AL QUOZ INDUSTRIAL AREA 3 – Dubai – United Arab Emirates