Alloy 50 Plate Supplier in India

Alloy 50 Plate Exporter in India

ALLOY 50 ASME SA 240 PLATES EXPORTER IN INDIA, UNS S20910 ALLOY SHEETS, HIGH QUALITY ALLOY 50 PLATE STOCKHOLDER, HOT ROLLED ALLOY 50 PLATE STOCKIST, CORROSION RESISTANCE ALLOY 50 PLATE.

ALLOY 50 PLATE SUPPLIERS, ALLOY 50 HOT ROLLED PLATES, ALLOY 50 PLATE DISTRIBUTORS, DIN 1.3964 ALLOY STRUCTURAL STEEL PLATE DEALER, ASTM A240 ALLOY 50 COLD ROLLED SHEET MANUFACTURER IN INDIA.

- » What is Alloy 50 Plates ?

- » ASTM A240 Alloy 50 Cold Rolled Plate Specification

- » Alloy 50 Plate Material

- » UNS S20910 Alloy 50 Plate Equivalent Grades

- » Alloy 50 Chequered Plates Chemical Composition

- » Alloy 50 Hot Rolled Plates Application

- » Alloy 50 Plate & Sheets Price List

- » Types Of Alloy 50 Plates, Sheets & Coils

- Alloy 50 Plates

- Alloy 50 Sheets

- S20910 Alloy Plates

- UNS S20910 Alloy Bright plate

- DIN 1.3964 Alloy Structural Steel Plates

- Prime Alloy 50 Plate

- Alloy 50 Cold Rolled Sheet

- Corrosion Resistance Alloy 50 Plate

- UNS S20910 Alloy Sheets

- ASME SA 240 Alloy 50 Sheets

- ASTM A240 Alloy 50 Sheet

- High Quality Alloy 50 Plate

- Alloy 50 A240 Plates

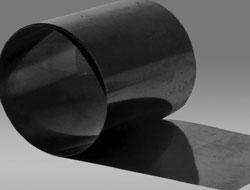

- Alloy 50 Coils

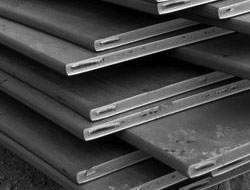

- Hot Rolled Alloy 50 Plate

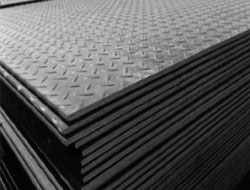

- Alloy 50 Chequered Plates

- ASTM A240 Cold Rolled Plates

- ASTM A240 Carpenter 50 Sheets

- Alloy 50 Diamond Chequered Plate

- ASTM A240 Carpenter 50 Plates

- Alloy UNS S20910 Plain Sheets

- ASTM A240 Alloy 50 Shim Sheet

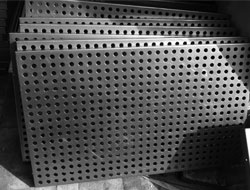

- ASME SA 240 Alloy 50 Perforated Sheet

- » Countries We Export Alloy 50 Sheet/Plate

- » Cities We Export Alloy 50 Sheet/Plate

What is Alloy 50 Plate ?

Alloy 50 Sheets (UNS R20501) is an austenitic, nickel-iron-chromium based super alloy with additions of Copper and Molybdenum which provide resistance to hostile environments, pitting, and crevice corrosion.50 alloy plate was designed specifically to withstand sulfuric acid. Its nickel, chromium, molybdenum and copper levels all provide excellent general corrosion resistance.Alloy 50 has good mechanical properties at both ambient and elevated temperatures, up to approximately 930°F (500°C) and is readily fabricated by usual industrial processes.

Reliable Steel distributors are prominent Manufacturer of Alloy 50 Plate in india.We are one of the leading Supplier of Alloy 50 Plate in india.We are in this domain more than 20 year, now we are dominant Exporter of Alloy 50 Plate in india.Reliable Steel distributors are ISO 9001:2008 Certified company and Biggest Stockholder and Stockist of Alloy 50 Plate in india, Kuwait, Oman, Saudi Arabia, UAE etc.Reliable Steel distributors are authoritative Distributor and Trader of Alloy 50 Plate in india.

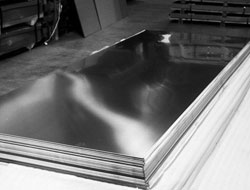

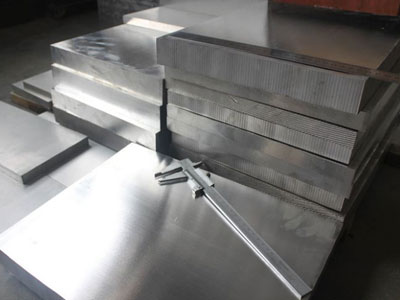

ASTM A240 Alloy 50 Sheet

ASME SA 240 Alloy 50 Plate

We manufacture Alloy 50 Plates, Sheets and Coils Using of latest technology.We continuously endure unopposed for our adaptability in creating Alloy UNS S20910 Plates.We offer Alloy DIN 1.3964 Plates, Incoloy 50 Sheets in various grades that meet the requirements of the client.With the consistent aid of highly experienced production team, we are completely adept in providing an extensive array of Alloy 50 Sheets With sincere intentions to serve our customers through qualitative products, we are actively engrossed in offering ASTM A240 Carpenter 50 Plates, ASTM A240 Carpenter 50 Sheets.Keep in mind about the requirement of our customers we provide Alloy 50 Coils, Incoloy 50 Coils, Incoloy 50 Plates in best quality and competitive price to fulfill each customers needs.

Why Choose Reliable Steel Distributors ?

- We are Leading Alloy 50 Plates Manufacturers in India

- We are ISO 9001:2008 Certified Alloy 50 Plates Suppliers in India

- We are Renowned Alloy 50 Plates Exporters in India

- We are 5th Largest Alloy 50 Plates Distributors in India

- Best Quality Alloy 50 Plates Traders in India

- Largest Alloy 50 Plate Stockist in India

- 4th Largest Alloy 50 Plate Stockholder in India

- Best Price Alloy 50 Plate Wholesaler in India

- Well Known Brand of Alloy 50 Plate Importers in India

- We are a Reputed Alloy 50 Plate Manufacturer in Mumbai, Maharashtra

- Alloy 50 Plate Manufacturers in Rajkot, Gujarat

ASME SA 240 Alloy 50 Plate Specification :

High Quality Alloy 50 Plate Equivalent Grades :

| STANDARD | WERKSTOFF NR. | UNS |

| Alloy 50 | 1.3964 | S20910 |

UNS S20910 Alloy 50 Plate Chemical Composition :

| Grade | Cr | Ni | Mo | Si | C | Fe | Mn |

| Alloy 50 | 22 | 12.5 | 2.25 | 1 | 0.06 | Bal | 5 |

Alloy 50 Plate Application :

Food Processing Industries

Oil & Gas Industries

Petrochemical Industries

Marine Industries

Alloy 50 Plate/Sheet Price List :

|

Materials

|

Price Range

|

Unit

|

|---|---|---|

|

S20910 Alloy 50 Plate

|

700-1000

|

USD/Ton

|

|

Alloy 50 UNS S20910 Alloy Sheets

|

1900-3500

|

USD/Ton

|

Types Of Alloy 50 Plates, Sheets & Coils :

Weight Calculator

How to calculate the weight

The weight is easily calculated. Simply multiply the appropriate alloy density by the length, width, and thickness of the required part (see worked example below).

| Metric | density (g/cm³) | x | T | x | W | x | L | = | weight |

| Example | 4.50g/cm³ | x | 6mm | x | 2m | x | 1m | = | 54.00 kg |

| Imperial | density (lbs/in³) | x | T | x | W | x | L | = | weight |

| Example | 0.163 lbs/in³ | x | 4in | x | 48in | x | 144in | = | 4506.6 lbs |

For imperial weight calculations certain measurements (fractions) need to be converted to decimal inches. For an accurate calculation it is also important to allow for the rolling tolerance which affects the thickness and the cutting tolerances which affect the width and length. These vary from thickness to thickness – please contact us for details.

Weight/Thickness

Density of steel

The acknowledged density of mild steel is 7.85 g/cm3 (0.284 lbs/in3). Depending on the alloy elements added to manufactured specifications this can vary between 7.75 and 8.05 g/cm3 (0.280 and 0.291 lbs/in3).

Sheet – Metric

| Thickness mm |

Size m |

Weight kg/sheet |

| 0.300 | 2 x 1 | 4.7 |

| 0.376 | 2 x 1 | 5.9 |

| 0.400 | 2 x 1 | 6.3 |

| 0.457 | 2 x 1 | 7.2 |

| 0.500 | 2 x 1 | 7.9 |

| 0.559 | 2 x 1 | 8.8 |

| 0.600 | 2 x 1 | 9.4 |

| 0.710 | 2 x 1 | 11.1 |

| 0.800 | 2 x 1 | 12.6 |

| 0.914 | 2 x 1 | 14.3 |

| 1.000 | 2 x 1 | 15.7 |

| 1.200 | 2 x 1 | 18.8 |

| 1.220 | 2 x 1 | 19.2 |

| 1.270 | 2 x 1 | 19.9 |

| 1.420 | 2 x 1 | 22.3 |

| 1.600 | 2 x 1 | 25.1 |

| 1.780 | 2 x 1 | 28.0 |

| 2.000 | 2 x 1 | 31.4 |

| 2.030 | 2 x 1 | 31.9 |

| 2.286 | 2 x 1 | 35.9 |

| 2.500 | 2 x 1 | 39.3 |

| 2.540 | 2 x 1 | 39.9 |

| 2.640 | 2 x 1 | 41.4 |

| 3.000 | 2 x 1 | 47.1 |

| 3.250 | 2 x 1 | 51.0 |

| 4.000 | 2 x 1 | 62.8 |

| 4.060 | 2 x 1 | 63.7 |

| 4.460 | 2 x 1 | 70.0 |

| 4.760 | 2 x 1 | 74.7 |

| 5.000 | 2 x 1 | 78.5 |

| 6.000 | 2 x 1 | 94.2 |

Sheet – Imperial

| Thickness in |

Size ft |

Weight lbs/sheet |

| 0.012 | 10×3 | 14.7 |

| 0.014 | 10×3 | 17.2 |

| 0.016 | 10×3 | 19.6 |

| 0.018 | 10×3 | 22.1 |

| 0.020 | 10×3 | 24.5 |

| 0.022 | 10×3 | 27.0 |

| 0.024 | 10×3 | 29.4 |

| 0.028 | 10×3 | 34.4 |

| 0.032 | 10×3 | 39.3 |

| 0.036 | 10×3 | 44.2 |

| 0.040 | 10×3 | 49.1 |

| 0.047 | 10×3 | 57.7 |

| 0.048 | 10×3 | 58.9 |

| 0.050 | 10×3 | 61.3 |

| 0.056 | 10×3 | 68.7 |

| 0.063 | 10×3 | 77.3 |

| 0.070 | 10×3 | 85.9 |

| 0.078 | 10×3 | 95.7 |

| 0.080 | 10×3 | 98.2 |

| 0.090 | 10×3 | 110.4 |

| 0.100 | 10×3 | 120.2 |

| 0.098 | 10×3 | 120.2 |

| 0.104 | 10×3 | 122.7 |

| 0.118 | 10×3 | 144.8 |

| 0.128 | 10×3 | 157.0 |

| 0.157 | 10×3 | 192.6 |

| 0.160 | 10×3 | 196.3 |

| 0.176 | 10×3 | 215.9 |

| 0.187 | 10×3 | 229.4 |

| 0.197 | 10×3 | 241.7 |

| 0.236 | 10×3 | 289.5 |

Plate – Metric

| Thickness mm |

Size m |

Weight kg/plate |

| 6.35 | 2 x 1 | 99.7 |

| 10.00 | 2 x 1 | 157.0 |

| 12.70 | 2 x 1 | 199.4 |

| 15.00 | 2 x 1 | 235.5 |

| 20.00 | 2 x 1 | 314.0 |

| 25.40 | 2 x 1 | 398.8 |

| 30.00 | 2 x 1 | 471.0 |

| 38.10 | 2 x 1 | 598.2 |

| 40.00 | 2 x 1 | 628.0 |

| 50.00 | 2 x 1 | 785.0 |

| 50.80 | 2 x 1 | 797.6 |

| 60.00 | 2 x 1 | 942.0 |

| 63.50 | 2 x 1 | 997.0 |

| 70.00 | 2 x 1 | 1099.0 |

| 76.20 | 2 x 1 | 1196.3 |

| 80.00 | 2 x 1 | 1256.0 |

| 90.00 | 2 x 1 | 1413.0 |

| 100.00 | 2 x 1 | 1570.0 |

| 101.60 | 2 x 1 | 1595.1 |

| 110.00 | 2 x 1 | 1727.0 |

| 120.00 | 2 x 1 | 1884.0 |

| 127.00 | 2 x 1 | 1993.9 |

| 130.00 | 2 x 1 | 2041.0 |

| 140.00 | 2 x 1 | 2198.0 |

| 150.00 | 2 x 1 | 2355.0 |

| 152.40 | 2 x 1 | 2392.7 |

Plate – Imperial

| Thickness in |

Size ft |

Weight lbs/plate |

| 1/4 | 10 x 3 | 306.7 |

| 1/2 | 10 x 3 | 613.4 |

| 3/4 | 10 x 3 | 920.2 |

| 1 | 10 x 3 | 1226.9 |

| 1 1/4 | 10 x 3 | 1533.6 |

| 1 1/2 | 10 x 3 | 1840.3 |

| 2 | 10 x 3 | 2453.8 |

| 2 1/2 | 10 x 3 | 3067.2 |

| 2 3/4 | 10 x 3 | 3373.9 |

| 3 | 10 x 3 | 3680.6 |

| 4 | 10 x 3 | 4907.5 |

| 5 | 10 x 3 | 6134.4 |

| 5 1/2 | 10 x 3 | 6747.8 |

| 6 | 10 x 3 | 7361.3 |

Density based on 7.85 g/cm3

(0.284 lbs/in3)

Alloy 50 Plate/Sheet Forming processes :

Rolling

Punching

Press Brake Forming

Perforating

Photochemical Machining

Laser Cutting

Incremental Sheet Forming

Hemming And Seaming

Deep Drawing

Bending

Spinning

Stamping

Packing of ASME SA240 Alloy 50 Plate :

Countries We Export Alloy 50 Sheet/Plate :

India, Costa Rica, Iran, Qatar, Hungary, Azerbaijan, Poland, Ukraine, Mexico, Poland, Belgium, Sweden, Chile, Algeria, Serbia, Ghana, Afghanistan, Belarus, Greece, Venezuela, Canada, Jordan, Ecuador, Nepal, Lebanon, United States, Mexico, Bahrain, Argentina, Nigeria, Mongolia, Chile, Peru, Russia, Israel, New Zealand, Lithuania, Kazakhstan, Yemen, Indonesia, Nigeria, Pakistan, Kuwait, Norway, South Africa, Taiwan, Malaysia, Bolivia, China, Denmark, Thailand, Libya, Tibet, Saudi Arabia, Spain, Sri Lanka, Romania, Trinidad & Tobago,Tunisia, Austria, Morocco, Portugal, Namibia, United Arab Emirates, Bulgaria, Vietnam, United Kingdom, Egypt, Bangladesh, Switzerland, Germany, Italy, Gabon, Finland, Slovakia, Turkey, Brazil, Croatia, Colombia, Oman, Iran, Philippines, Gambia, Estonia, Angola, Macau, Zimbabwe, Netherlands, Puerto Rico, France, Singapore, Australia, Hong Kong, Japan, Iraq, Bhutan, Ireland, Kenya, Czech Republic, South Korea.

Cities We Export Alloy 50 Sheet/Plate :

New York, Jeddah, Cairo, Houston, New Delhi, Karachi, Chiyoda, Tehran, Mexico City, Vung Tau, Montreal, Ulsan, Navi Mumbai, Howrah, Ahmedabad, Caracas, Thane, Mumbai, Surat, Indore, Manama, Toronto, Faridabad, Gimhae-si, Bogota, Ho Chi Minh City, Sharjah, Hanoi, Dallas, Hong Kong, Abu Dhabi, Algiers, Chennai, Riyadh, Los Angeles, Busan, Kanpur, Ankara, Doha, Jakarta, Coimbatore, Rajkot, Calgary, Seoul, Sydney, Brisbane, Kuala Lumpur, Moscow, Colombo, Ranchi, Istanbul, Kuwait City, Geoje-si, Petaling Jaya, Kolkata, Dubai, Bhopal, Perth, Baroda, Atyrau, Rio de Janeiro, Al Jubail, Secunderabad, Bengaluru, Pimpri-Chinchwad, La Victoria, Milan, Ahvaz, Hyderabad, Muscat, Santiago, Port-of-Spain, Nagpur, Noida, Ernakulam, Edmonton, Gurgaon, Aberdeen, Courbevoie, Madrid, Jamshedpur, Visakhapatnam, Al Khobar, Bangkok, Ludhiana, Melbourne, Granada, Lagos, Haryana, Pune, Lahore, Thiruvananthapuram, Singapore, Dammam, Jaipur, Chandigarh, Vadodara, London, Nashik.